SERVICES

Automotive Industry

ADVANTAGES

How does VEMORI work?

Delivered on time:

We understand the challenges with suppliers who do not meet deadlines or quality standards; that’s why we have certified processes and big production controls.

Production capacity:

We handle volumes exceeding 12,500 pieces per month, with scalability adaptable to customer requirements.

Joint technical development:

We offer design support, measurement, testing and product validation according to the client’s engineering timelines.

Logistical flexibility:

We work under Just-in-Time (JIT) conditions, Kanban or consignment, according to the needs of each plant.

Prototyping and validation:

We have in-house capabilities for prototype evaluation, assembly review and functional testing.

Customized packaging and delivery:

We design safe packaging solutions, optimized for each production line.

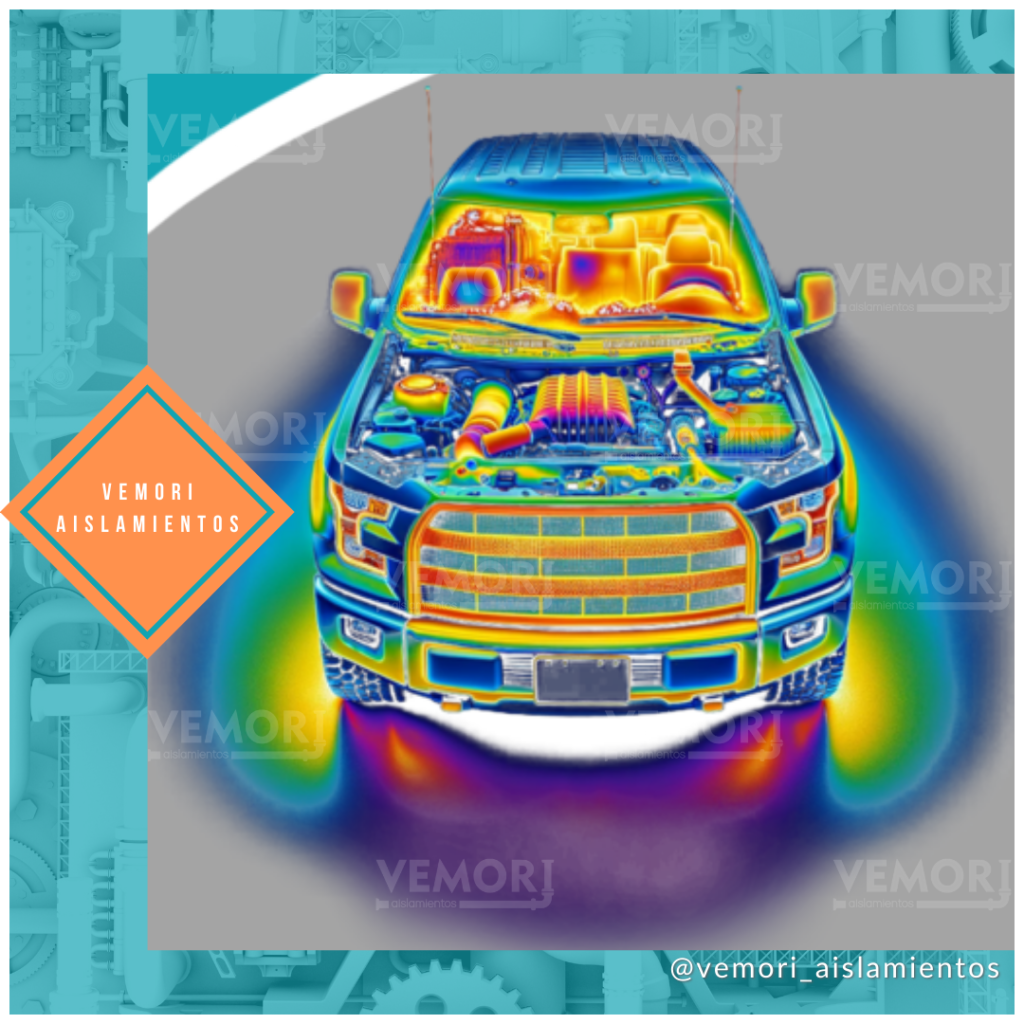

Our insulation is designed for various automotive systems

Materials and Applications

Vehicle system

Hood and firewall

Floor and exhaust tunnel

Doors and interior panels

Exhaust system

Type of insulation

Acoustic / thermal

Acoustic / thermal

Acoustic

Thermal

Available materials

Fiberglass, acoustic foam, aluminum-coated sheet.

Thermoformed felts, aramidic material and compositions for high temperature.

Foams PU / PE, viscous elastic materials, non-absorbent fabrics.

Fiberglass mads, silicone and aramid with teflon lining or stainless steel.

SOLUTIONS

Why choose VEMORI thermal insulation for your vehicles?

In VEMORI, we are committed to excellence and quality, certified under the ISO 9001 standard, ensuring the highest management standards. We adapt to the rigorous methods of the automotive supply chain to guarantee on-time deliveries and consistent products.

Our focus on continuous improvement and the customer satisfaction drives us to work closely with our partners, using advanced technologies and optimized processes to offer thermal insulation solutions that exceed the expectations of the automotive sector.

Join at the automotive industry who trust in VEMORI to increase efficiency, security and enhance the comfort of your vehicles with our customized, high-quality solutions.

ADVANTAGES

VEMORI EN EL SECTOR AUTOMOTRIZ

Turbochargers

The purpose of a turbocharger (turbo) is increase the amount of air entering the engine to generate more power. This is achieved by using the engine’s exhaust gas flow to drive a turbine inside the turbocharger. This turbine can rotate at speeds higher than 200,000 rpm, causing it to generate considerable heat. Because the heat is greater and pressure is greater when the gas comes out, more faster the turbine will spin and more air will be pushed into the engine cylinders by the compressor.

However, this heat has implications for safety and the engine performance. A hot turbocharger exposed can be present a danger for teh personal safety and this can negatively affect nearby heat-sensitive components. Increased heat can increase stress on the piston, the piston rings, the cilider pipe and the cylinder head of the engine.

Although the air coming out of the turbo compressor isn’t very hot, the the air comes out is hot, because compression raises its temperature (around 200°C/400°F in typical diesel engines). Hot air is less dense than cold air, this means that less air can be introduced into the engine cylinders, limiting the effectiveness of the turbocharger. This is where charge air coolers come into play.

Charge Air Coolers

The work of “Charge Air Cooler” (intercooler or aftercooler) is take the compressed air and cool down before it goes into the engine.This denser air allows more air to be introduced into the engine cylinders, improving turbocharger efficiency.

How does VEMORI Thermal Insulation help?

For turbochargers, a properly designed removable insulating blanket and placed at the top of the «hot side» of the turbo helps to maintain appropriate temperatures. This keeps the heat on the hot side and prevent it from affecting the cold side, it will allow the turbo to work efficiently. In addition , it is protecting nearby components that could be affected by the high temperatures generated by an exposed by a turbocharger. Finally, security is improved: a turbocharger with a removable insulation blanket will protect people from accidentally burning themselves on an otherwise very hot engine component.

For charge air coolers, removable insulation blankets are mainly placed on the piping that runs from the turbo to the compressor, cooler and radiator. These pipes can be at over 400°F in diesel applications (more higher in gas applications), it could pose a danger to staff if not properly isolated. Cover these pipes with removable insulation blankets reduces the temperature of touch-sensitive surfaces to safe levels.

Transforming the Efficiency and Safety of Your Vehicle with VEMORI

The VEMORI thermal insulation not only improves efficiency and the performance of turbochargers, also increases security and protects critical engine components. With our removable insulation solutions, you can be sure that your vehicle will function optimally, safely and efficiently.