If you're considering installing removable thermal insulation, you've probably asked yourself two key questions:

How long does a removable thermal blanket last? and Can I insulate only part of the system to save money?

The reality is that, while partial insulation may seem like a quick and inexpensive solution, in many cases it ends up being inefficient, risky, and more costly. In this article, we explain why.

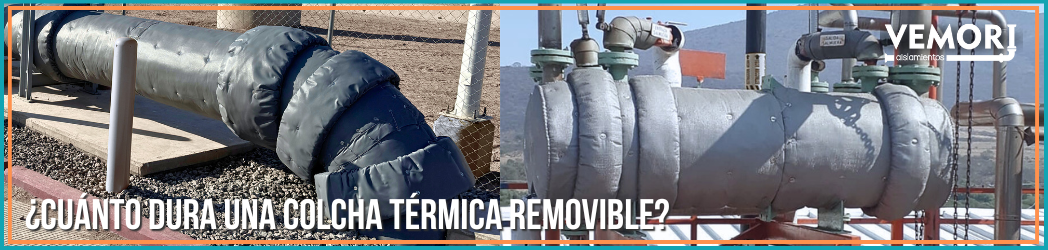

What is a removable thermal blanket?

A removable thermal blanket is an insulation system designed to protect industrial equipment from high or low temperatures. Its key feature is that it can be easily removed and reinstalledwithout tools or damaging the material.

At VEMORI, our blankets are composed of three main layers:

- Hot (inner) layer: made with stainless steel mesh or treated fabric to withstand temperatures up to 1260°C.

- Insulating filler: generally ceramic or fiberglass fiber, with thicknesses ranging from 1" to 4", depending on the required heat reduction.

- Cold side (external): designed to protect the insulation from the environment, made with fiberglass fabric coated with silicone, Teflon, or aluminized materials.

They also include fastening systems such as industrial Velcro, straps, or rings, which guarantee a firm and reusable fit.

How long does a removable thermal blanket last?

Under normal operating conditions, a well-designed removable thermal blanket can last between 5 and 9 years.

Its durability will depend mainly on:

- The operating temperature of the equipment.

- The frequency with which it is removed for maintenance.

- The type of environment (indoor or outdoor, dry or humid, with or without chemicals).

- The quality of the materials and stitching.

At VEMORI, we use only high-performance textiles, selected based on the thermal analysis of the equipment. Furthermore, we manufacture each blanket to measure, ensuring that the insulation functions optimally from day one.

While a generic, low-quality blanket might wear out in just 2 or 3 years, well-maintained VEMORI blankets can last over 8 years without compromising performance.

What happens if you only insulate part of the system?

Often, due to budget constraints or hasty decisions, only a section of the system is insulated (a valve, a section of pipe, a heat exchanger, etc.). However, this can lead to technical and safety problems::

1. Thermal Leakage

Heat escapes through uninsulated areas, drastically reducing the system's efficiency. This means that even if part of the system is covered, energy loss still occurs.

2. Thermal Shock and Uneven Wear

When some parts of the system are insulated and others are not, significant temperature differences are created. This can cause deformation, cracks, or even failures in flanges, valves, or gaskets.

3. Damage to Nearby Components

Sensors, electrical wiring, paint, seals, or electronic systems located near uninsulated areas can deteriorate rapidly due to excessive heat.

4. Risk to Personnel

Unprotected areas continue to pose a latent danger to operators, especially when working near valves, turbines, or high-temperature equipment.

5. False Perception of Efficiency

Many companies insulate only a portion and believe they are saving energy. However, in practice, partial insulation does not achieve the expectedand can create a false sense of compliance with safety regulations.

So, is complete insulation the right solution?

Yes. It is always better to consider the entire system, even if the insulation is installed in stages.

At VEMORI, when we receive a project, we don't just quote a blanket: we make a customized thermal study to define which parts of the system need to be covered, which materials are suitable, and how to optimize the design to facilitate future maintenance.

Our blankets:

- Are custom-made.

- They are installed without tools.

- They comply with quality and safety standards.

- They are reusable.

- They have a minimum 12-month warranty (extendable depending on conditions).

A real-world example?

In one of our most recent projects, a power plant decided to insulate only the main valves of its steam system. Shortly after, they discovered that the uncovered sections of pipe were still radiating heat , and the temperature sensors were malfunctioning due to excessive exposure.

The solution was clear: complete insulation, specifically designed for the system's conditions. After implementing the VEMORI solution, the following was achieved:

- Reduction of surface temperature from 220°C to 55°C.

- Elimination of direct contact risks.

- Improvement of system efficiency by 25%.

- Protection of all nearby electronic components.

A removable thermal blanket can last for many years, but only if it is properly designed and applied comprehensively.

Insulating only part of your system may seem like a way to save money, but in practice it can lead to more losses, risks, and maintenance.