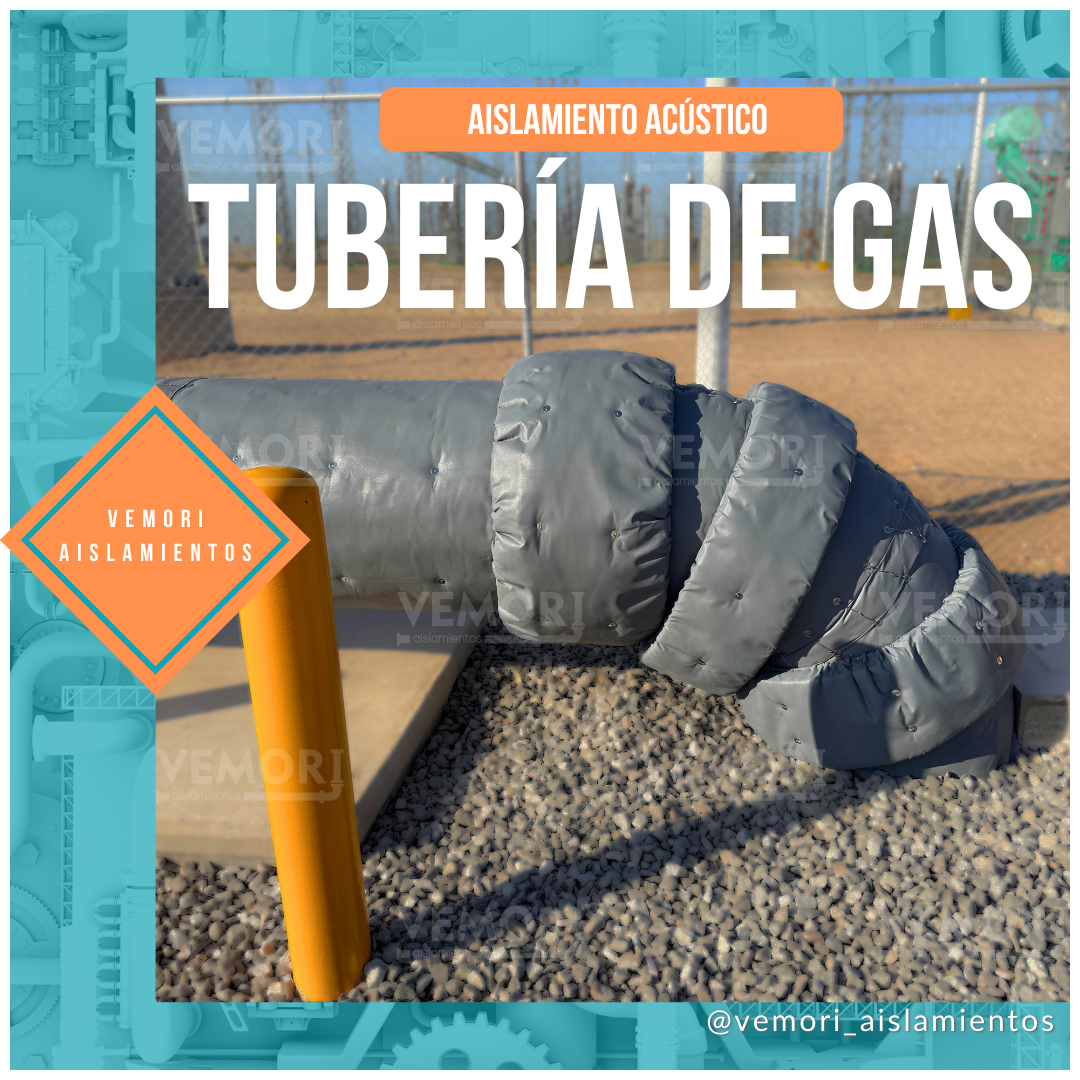

Gas Pipe

Industrial solution for noise reduction and vibrations in gas lines. Adapted to severe conditions and safety regulations.

Description

Noise Reduction in Demanding Industrial Environments.

Noise Control and Regulatory Compliance in Industrial Facilities.

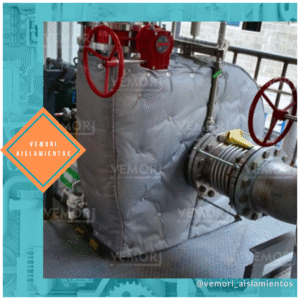

Acoustic insulation applied to gas pipelines is a specialized solution that effectively reduces the transmission of structural and airborne noise generated by the passage of high-pressure gases, valves, compressors, or expansion points. At Vemori, we design and install acoustic insulation systems tailored to the operating conditions of each plant, using high-performance materials that resist temperature, vibration, humidity, and chemicals.

This type of insulation not only improves the acoustic comfort of the industrial environment but also contributes to compliance with occupational health and safety standards by preventing prolonged worker exposure to noise.

Key Benefits:

-

Significant reduction of noise generated by gas flow

-

Reduction of vibrations and resonances in the pipeline network

-

Improved work environment and compliance with OSHA and NOM regulations

-

Additional thermal protection, if combined insulation is required

-

Customized installation according to diameters, routes, and system conditions

Common Applications:

-

Natural gas or LP gas lines in industrial plants

-

High-pressure internal distribution networks

-

Combustion systems or industrial thermal processes

-

Noise-sensitive areas such as control rooms or laboratories

Acoustic solutions designed for industry.

At Vemori, we have the experience and the right materials to guarantee efficient acoustic insulation of gas pipelines, with safe, durable solutions adapted to the most demanding operating conditions.

DESCRIPTION

Thermoacoustic insulation made of low-density fiberglass, bonded with heat-curing phenolic resin, presented in pink rolls, either uncoated or with asphalt-coated kraft paper.

USES AND APPLICATIONS

Aislhogar is recommended as thermal and acoustic insulation in the construction industry, for use inside walls and partitions, above suspended ceilings, and as a sound absorber under certain types of flooring and within drywall systems.

ADVANTAGES

Maximum thermal efficiency: With the lowest thermal conductivity of any other insulator of its type, it guarantees minimal heat loss or gain and substantial savings in residential and commercial construction systems.

Maximum acoustic efficiency: This product is one of the most efficient sound-absorbing products offered by Owens Corning, helping to create a quieter and more comfortable environment.

Does not promote corrosion: The non-ferrous nature of the fiberglass does not promote corrosion of steel, copper, and aluminum, resulting in a longer lifespan for equipment and installations.

Vibration resistance: The diameter and length of our fibers, in addition to the type of fiber binding, result in zero shot (0% shot). This prevents the insulation from detaching from residential and commercial building systems subject to vibrations that transmit noise. By maintaining its original shape, it preserves uniformity in thermal conductivity and heat or cold flow throughout, as well as noise transmission.

Easy to install and handle: Due to its density, flexibility, and ease of handling, it is a material that is quick to install and adapts to the irregular surfaces of building systems, maximizing installation productivity without damaging the building structure.

Low maintenance and long lifespan: It is characterized by its long lifespan, resulting in minimal maintenance costs and very long-term insulation replacement in a well-installed system.

Economical: Due to its thermal and acoustic efficiency, durability, ease of installation, versatility, and price, Aislhogar is the most economical material of its kind in the market for thermoacoustic insulation for residential and commercial applications.

Resilient: The characteristics of the rolls and the properties of fiberglass allow the material to recover its shape and thickness once the deforming pressure is removed, ensuring its R-value (Thermal Resistance).

Inorganic and odorless: Fiberglass does not promote the growth of fungi or bacteria, thus preventing odors and extending the material's lifespan.

Dimensionally stable: This product does not expand or contract when exposed to significant temperature changes, preventing the formation of gaps that could allow heat, cold, or sound to escape or enter.

Non-combustible (without coating): Its non-combustible nature and components prevent the risk of fire spread, reducing fire insurance premiums.