In the industrial field, choosing the appropriate removable thermal insulation is crucial to optimize energy efficiency, reduce operating costs and ensure the optimal functioning of equipment and processes. With a wide variety of options available on the market, it is important to carefully consider your company's specific needs before making a decision. In this detailed guide, we offer you the key steps to select the best removable thermal insulation according to your industrial requirements.

Step 1: Identify objectives and needs

The first thing you should do is clearly identify the objectives you want to achieve with removable thermal insulation. Ask your operations and maintenance team what the main challenges are in terms of energy efficiency and maintenance. Some points to consider include:

- Reduction of heat or cold losses.

- Improvement in energy efficiency and reduction of operating costs.

- Ease of maintenance and access to equipment.

- Protection against corrosion and mechanical wear.

- Compliance with environmental regulations and standards.

Step 2: Evaluate the types of removable thermal insulation available

There are different types of removable thermal insulation, each with specific characteristics and applications. The most common include:

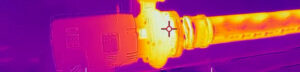

- Insulating blankets: They are versatile and adapt to different shapes and sizes of equipment and pipes.

- Removable coatings: Provide a thermal barrier resistant to high temperatures and corrosive environments.

- Insulating covers: Ideal for protecting hard-to-access components.

It is important to understand the advantages and limitations of each type to make an informed decision.

Step 3: Consider the materials and their thermal resistance

Materials used in removable thermal insulation have a significant impact on its efficiency and durability. Look for materials with high thermal resistance and that are suitable for the specific temperatures and conditions of your industry. The most common materials include fiberglass, rock wool, airgel and ceramic materials.

Step 4: Evaluate ease of installation and disassembly

Effective removable thermal insulation must be easy to install and remove. Consider those systems that allow quick and easy access to equipment for inspections and maintenance. Ease of disassembly also makes it easy to replace or repair damaged parts, extending the life of the insulation.

Step 5: Customization and adaptability

Each industry has specific needs, so it is essential to choose removable thermal insulation that can be customized and adapted to your company's equipment and processes. Look for suppliers who offer tailored solutions and who are willing to work with you to meet your particular requirements.

Step 6: Review success stories and testimonials

Before making a final decision, research and review success stories of companies that have implemented the type of removable thermal insulation you are considering. Testimonials and experiences from other companies can give you a clear idea of the benefits and possible challenges associated with each option.

Step 7: Evaluate the cost-benefit

While the initial cost is a factor to take into account, it is also essential to evaluate the long-term cost-benefit. Consider energy savings, reduced operating costs, and increased equipment life to determine the return on investment (ROI) offered by each type of removable thermal insulation.

Selecting the appropriate removable thermal insulation for your company is a strategic decision that will impact the efficiency and profitability of your operations. By following this detailed selection guide and considering the specific needs of your industry, you will be prepared to make an informed decision and take full advantage of the benefits these systems can offer. Quality removable thermal insulation will not only reduce heat or cold losses, but will also improve the energy efficiency of your company and promote more sustainable and environmentally responsible practices.

Contact Vemori to receive the best advice on our ideal insulation for your industry.