Diesel and gas engines commonly have two turbochargers to increase engine efficiency; one operates in hot conditions and the other in cold conditions and both use removable thermal insulation, we are referring to turbochargers and charge air coolers.

Turbochargers:

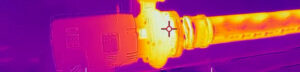

The purpose of a turbocharger (commonly known as a turbo) is to increase the mass of air entering the engine to generate more power, this is possible by using the flow of exhaust gases from an engine to drive a turbine located inside the turbo housing, this is why they heat up, coupled with this, the internal turbine can rotate at speeds above 200. This is important because the higher the heat and pressure resulting from the exhaust, the faster the turbine will spin and the more air will be pushed into the engine cylinders by the compressor.

However, heat has implications for safety and engine performance. An exposed hot turbocharger can pose a personal hazard, as well as negatively impact nearby heat-sensitive components. Increased heat can increase stress on the piston, piston rings, cylinder liner, and engine head.

While the air leaving the compressor section of the turbocharger is not as hot as the exhaust (since the compressor is drawing in ambient air and not exhaust air), the act of compression causes the air temperature to rise (per typical diesel engine, around the 200°C / 400°F mark). Since hot air is not as dense as cold air, less air can be drawn into the engine cylinders, which in turn limits the efficiency of the turbocharger. This is where charge air coolers come into play.

Charge air coolers:

The job of the "Charge Air Cooler", also known as the "intercooler" or "aftercooler", is to take compressed air and cool it before it enters the engine, this resulting air is denser and therefore more air can be packed into the engine cylinders than could have been achieved with the hot air coming out of the turbocharger.

How does VEMORI thermal insulation help?

In the case of turbochargers, a properly designed removable insulation blanket placed on top of the "hot side" of the turbocharger helps maintain proper temperatures, preserving heat on the hot side and preventing damage to the cold side, allowing the turbo to work efficiently. Nearby components that could be affected by the extremely high ambient temperatures generated by an exposed turbocharger are also protected. Finally, increasing safety, a turbocharger with a removable insulation blanket will protect people from accidentally burning themselves on an otherwise hot engine component.

For charge air coolers removable insulation blankets are found primarily in the piping leading from the turbo to the compressor, cooler and radiator. The cooler may be somewhat remote from the turbo and the piping which can be over 400° F for diesel applications (on gas it would be higher) represents a hazard to personnel if not properly insulated. Covering these pipes with removable insulation blankets reduces the temperature of touch-sensitive surfaces to safe levels.

For more information on how VEMORI can help you with your motor insulation needs, you can call us at: +52 33 1356 8367

Written by: Ing Octavio Velazquez Rizo

Project manager

octavio@vemori.com