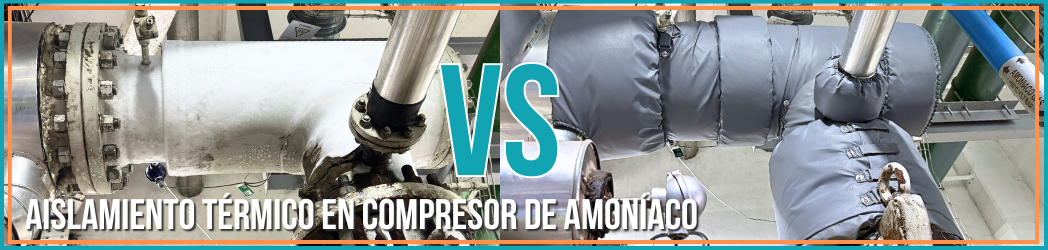

Thermal Insulation in Ammonia Compressors

In industry, condensation in equipment operating at low temperatures not only represents an operational risk but also a safety and efficiency problem. Leaks, slippery floors, freezing, and potential contamination can arise if this phenomenon is not properly controlled. At Vemori Insulation, specialists in removable and fixed thermal insulation, we know that the solution lies in intelligent, practical, and durable protection.

This article addresses how to prevent condensation in industrial equipment, especially ammonia compressors, through the use of high-efficiency removable thermal insulation.

What is condensation and why does it occur in industrial equipment?

Condensation occurs when water vapor in the air comes into contact with cold surfaces, such as those of equipment handling refrigerants or gases at low temperatures. The result is the formation of water droplets that can:

- Accumulate on the floor and create slip hazards.

- Cause corrosion or long-term damage to machinery.

- Affecting quality and safety in sensitive areas such as the food industry.

- Increasing maintenance costs.

Real-world case: Condensation in ammonia compressors

A common example is found in ammonia compressors, widely used in industrial refrigeration systems. Without proper insulation, these units suffer from ice formation and water runoff, creating hazardous and inefficient environments.

In a recent project carried out by our team, it was identified that the equipment had severe freezing and condensation problems. The accumulation of water in the work area posed a threat to both personnel and the plant's operating standards.

The solution: Removable thermal insulation

The Vemori's removable thermal insulation was specifically designed to cover each critical part of the compressor:

- Compressor body

- Connection flanges

- Inlet and outlet pipes

- Sections with varying diameters

- Identification plates and sensors

This system prevents ice formation and eliminates condensation by creating an effective barrier against heat exchange with the environment.

Benefits of Removable Insulation Compared to Other Methods

The use of removable thermal insulation in industrial equipment offers multiple benefits that directly impact the safety, efficiency, and cost-effectiveness of operations. First, it prevents condensation by keeping cold surfaces from coming into contact with humid air, thus eliminating the formation of water droplets and ice buildup. This significantly reduces the risk of slips, falls, and potential contamination in the work area. Furthermore, it improves personnel safety by maintaining cleaner and more stable conditions. Another key benefit is ease of maintenance. Because they are removable, thermal blankets can be taken out and reinstalled without affecting their integrity, saving time and reducing operating costs. These systems are reusable, allowing for extended use in future services and optimizing resources. Finally, they contribute to greater equipment durability. By maintaining a more stable temperature, they reduce wear from sudden temperature changes and improve the overall performance of industrial components.

Why Choose Vemori Insulation?

In Vemori Insulation, we design and install custom industrial thermal insulation solutions, specializing in removable and reusablesystems. Our approach is based on understanding each client's specific challenges and offering practical, clean, and scalable solutions that do not interfere with equipment operation.

We have experience with demanding production lines in industries where precision, hygiene, and safety are paramount.

Applications of Removable Insulation

- Industrial compressors (ammonia, CO₂, etc.)

- Heat exchangers

- Refrigeration valves and flanges

- Cold liquid storage tanks

- Cryogenic process piping

Maintenance and Durability

Removable insulation is manufactured with weather-resistant and easy-to-clean materials. It requires minimal maintenance, extending the lifespan of the protected equipment. Furthermore, its modular design facilitates storage and reuse during scheduled maintenance.

Condensation in industrial equipment should not be taken lightly. Preventing condensation with removable thermal insulation not only improves safety but also represents long-term savings and a significant improvement in operational efficiency.

If you have equipment experiencing condensation or temperature loss, at Vemori Insulation we can help you find the ideal solution. Our commitment is turning your thermal needs into real and removable solutions.