While the importance of thermal insulation in industrial facilities is widely recognized, the quality and effectiveness of such insulation is often overlooked. Inadequate thermal insulation can present serious risks that go beyond mere energy waste. This article sheds light on the short, medium and long term risks associated with poor thermal insulation.

Short-term risks

Energy inefficiency

- Impact: An inefficient insulation system results in increased energy needs to maintain optimal operating conditions, which increases operating costs.

Unsafe working conditions

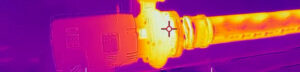

- Impact: Lack of adequate insulation can lead to the formation of “hot spots” on machinery, posing a burn or fire risk.

Equipment deterioration

- Impact: Condensation and corrosion are more likely if the insulation system is inadequate, which can lead to reduced equipment life and premature failure.

Medium-term risks

High operating costs

- Impact: Cumulative energy costs can be significant if inefficiency is allowed to persist.

Health and safety issues

- Impact: Continued exposure to extreme temperatures or toxic materials due to inadequate insulation can put employee health at risk.

Structural damage

- Impact: Pooled water and thermal stress can lead to structural damage to facilities, which may require costly repairs.

Long-term risks

System failure

- Impact: As problems accumulate, the risk of a complete system failure becomes increasingly likely.

Non-compliance with regulations

- Impact: Regulations around energy efficiency and carbon emissions are becoming stricter. Poor insulation could result in fines or even facility closure.

Damaged reputation

- Impact: Sustainability is an increasingly important topic for consumers and investors. Energy inefficiency and safety issues can negatively affect a company's reputation.

How to avoid these risks?

- Insulation Audits: Conduct regular inspections to evaluate the effectiveness of insulation.

- Consult Experts: Get advice from experts in industrial thermal insulation to install the most appropriate materials and systems.

- Regular Maintenance: Maintain and repair the insulation system to ensure its effectiveness over time.

Do not underestimate the importance of adequate thermal insulation in your industrial facility. The risks associated with poor insulation are multiple and can have serious implications in the short, medium and long term. By taking a proactive and well-informed approach, these risks can be effectively mitigated.

If you have any questions or need a consultation, we are here to help. Feel free to contact us for a customized insulation solution.

For more information and to schedule a consultation, please contact us through our social networks and our website.

Stay informed about the best practices in industrial thermal insulation by following our blog and social networks.